Understanding Rotogravure Printing Process

What is Rotogravure?

Rotogravure, often referred to simply as gravure, is a high-quality, high-speed printing process that is commonly used for packaging, labels, and magazines. This printing technique involves engraving the image or text to be printed onto a cylinder, which is then used to transfer the ink onto the printing surface. Unlike other printing methods, rotogravure uses a rotary printing press where the substrate (material to be printed on) passes through in a continuous roll. This method is renowned for its ability to produce sharp, detailed images with rich colours and gradients, making it ideal for printing on flexible packaging materials.

How Rotogravure Works

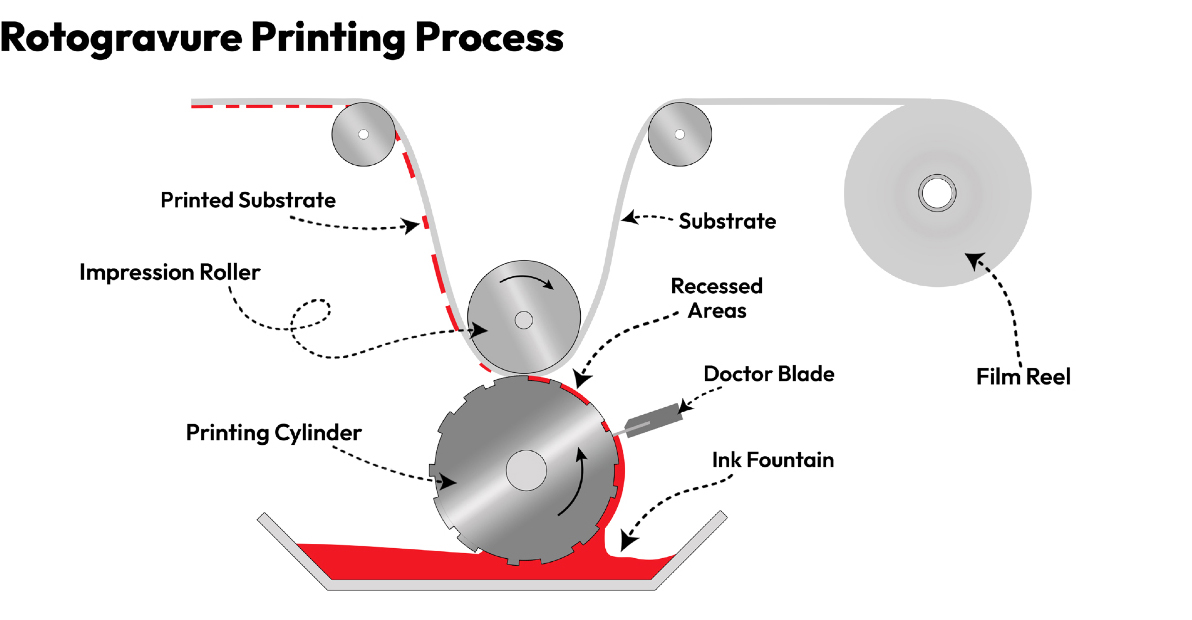

1. Engraving the Cylinder: The first step in the rotogravure printing process involves preparing the printing cylinder. The image or design to be printed is engraved onto a large metal cylinder. This engraving is done using either an electronic engraving machine or a laser, depending on the required precision and quality. The engraved areas are recessed, which will later hold the ink.

2. Inking the Cylinder: Once the cylinder is engraved, it is dipped into an ink fountain. The recessed areas of the cylinder fill with ink, while the surface of the cylinder is wiped clean using a doctor blade. This blade removes the excess ink from the non-engraved areas, ensuring that only the recessed areas carry ink.

3. Transferring the Ink: The printing substrate, which could be paper, plastic, or foil, is fed between the printing cylinder and a rubber-coated impression roller. As the cylinder rotates, the substrate comes into contact with the ink-filled recessed areas. The ink is transferred from the cylinder to the substrate, creating the desired image or text resulting in a printed substrate. This process is repeated for each colour in the design, using separate cylinders for each colour.

4. Drying the Ink: After the ink is transferred, the printed substrate passes through a drying system. Rotogravure inks are typically solvent-based, meaning they dry quickly when exposed to heat or air. The drying process ensures that the ink sets correctly and prevents smudging or bleeding between colours.

5. Rewinding and Finishing: Once the printing and drying processes are complete, the printed material is rewound onto rolls. These rolls are then cut, laminated, or processed further, depending on the end-use application.

Rotogravure in Custom Printed Stand Up Pouches

Stand-up pouches are a popular packaging solution for a wide range of products, including food, beverages, and personal care items. The unique design of these pouches allows them to stand upright on store shelves, offering excellent visibility and appeal to consumers. Rotogravure printing is a preferred method for customizing stand-up pouches due to several key advantages:

1. High-Quality Print: Rotogravure printing is known for its ability to produce high-resolution images with fine details, smooth gradients, and vibrant colours. This quality is crucial for custom printed stand-up pouches, as it helps brands create eye-catching designs that attract customers. The precision of rotogravure ensures that even the smallest text or intricate patterns are printed clearly.

2. Consistency: Rotogravure printing provides consistent results across large production runs. Once the cylinders are engraved and set up, the process can be repeated multiple times without significant variation in print quality. This consistency is essential for maintaining brand identity, as it ensures that every pouch looks the same, regardless of the batch.

3. Durability: Stand-up pouches need to withstand various handling conditions, from transportation to display on store shelves. Rotogravure printing uses inks that are resistant to wear and tear, as well as exposure to light and moisture. This durability ensures that the printed design remains intact and legible throughout the pouch's lifecycle.

4. Versatility: Rotogravure is compatible with a wide range of materials used for stand-up pouches, including plastic films, foil laminates, and paper. This versatility allows manufacturers to choose the best material for their product while still achieving high-quality prints. Additionally, rotogravure can handle multiple colours and complex designs, making it suitable for both simple branding and elaborate graphics.

5. Efficiency: For large-scale production, rotogravure is highly efficient. The process allows for high-speed printing, which reduces production time and costs. The engraved cylinders can also be reused for future print runs, providing a cost-effective solution for brands that require regular production of their custom printed stand-up pouches.

Advantages of Using Rotogravure for Stand Up Pouches

- High Image Quality: The ability to print with fine detail and precision makes rotogravure ideal for branding and product information.

- Large Volume Efficiency: The process is optimised for long print runs, making it economically viable for large-scale production.

- Consistent Colour: The method ensures that colours remain consistent throughout the print run, which is vital for brand recognition.

- Durable Prints: The prints produced by rotogravure are resistant to smudging and wear, maintaining their appearance over time.

- Adaptability: Suitable for a wide variety of substrates and inks, including metallic and specialty inks that add unique effects to the packaging.

Conclusion

Rotogravure printing is a highly effective and reliable method for creating custom printed stand up pouches. Its ability to deliver exceptional print quality, consistency, and durability makes it the preferred choice for brands looking to create attractive and functional packaging solutions. Whether for food, cosmetics, or other consumer goods, rotogravure printing ensures that stand-up pouches not only protect the product inside but also enhance its appeal and visibility on store shelves.